Baby Girl Clothes Bamboo Source Manufacturer Top

The Elevated Role of Aesthetic Appeal in Infant Fashion

In the dynamic universe of infantwear, baby Girl Clothes Bamboo has emerged as a touchpoint where sustainability meets timeless beauty. Aesthetic sensibilities in this market segment are increasingly refined, driven by parents seeking a balance between charming visuals and wellness-considered materials. For meticulous attention to design, the integration of motifs like pastel flowers, scalloped embroidery, and nature-inspired elements has become paramount. Soft lavender, muted peach, and dusky rose dominate color charts, aligning with color psychology directives that prioritize tranquility and positivity. These hues enhance emotional connections, making every piece a statement of gentle care.

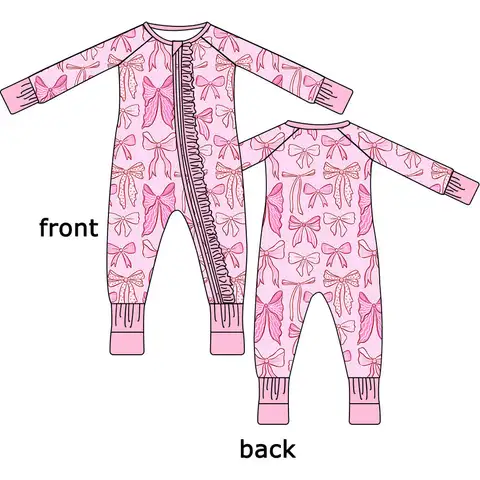

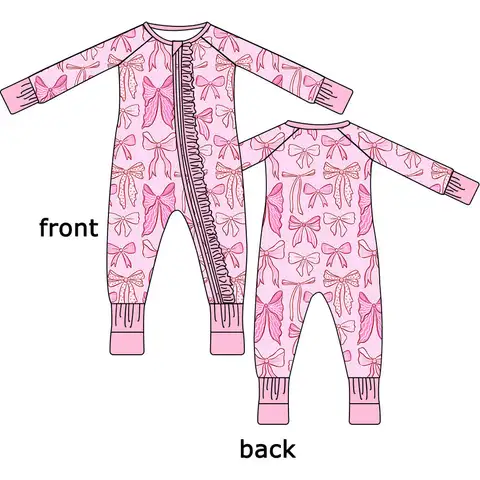

Simplified Ergonomics in Baby Girl Clothes Bamboo Design

Ergonomics in baby Girl Clothes Bamboo has transcended conventional form into a science of marrying material performance with infant anatomical considerations. Bamboo fibers, recognized for their hypoallergenic properties and breathability, ensure that every garment provides a non-irritating interface between the baby's skin and the environment. Flatlock seams, pressure-free elastics, and snap buttons engineered to AQL 2.5 standards prevent fabric inconsistencies often encountered in bulk shipping protocols. These technical specifications in ergonomic design safeguard comfort while maintaining production efficiency.

The suppleness of bamboo textiles lends itself to adaptive fits. Smocking and elasticated waistbands are pivotal add-ons, allowing garments from rompers to sleep sets to flex along with a baby’s natural movements. By incorporating lightweight knit patterns and three-thread interlocking constructions, manufacturers are redefining the standards for ergonomic excellence in baby Girl Clothes Bamboo.

Innovative Insights on Color Psychology

Color psychology is intrinsic when developing baby Girl Clothes Bamboo. For infant girls’ wardrobes, there is a concerted shift toward palettes that resonate with serenity and joy. Studies affirm that cool tones—like serene powder blue and soothing mint—have calming effects on newborns, while warmer accents in blush pink awaken nurturing sentiments in caregivers. Strategic deployment of these colors in alternating panels, shoulder trims, and hem detailing achieves visual balance that not only appeals to buyers but also enhances the perceived value of the garment.

Color reflects a brand's ideology. Subdued tones signal class and environmental consciousness, compelling alignment with eco-centric buyers who prioritize sustainable choices while browsing for exclusive baby Girl Clothes Bamboo. Designers must thoughtfully blend seasonal tones while preserving brand identity markers, ensuring that each release evolves with consumer expectations.

Baby Girl Clothes Bamboo Supply Chain Solutions: Excellence and Scalability

The production pipeline for baby Girl Clothes Bamboo requires an integration of both agility and precision, especially as bulk orders dominate the fast-expanding B2B landscape. Custom-dyed bamboo yarn needs to meet OEKO-TEX certification benchmarks to ensure long-term durability and colorfastness. To meet growth demands, operational methodologies must exceed AQL 2.5 standards, mitigating defects pre- and post-shipping processes through state-of-the-art defect-detection robotics in weaving facilities.

Scalability includes partnerships with logistics providers who specialize in temperature-controlled environments to maintain the structural integrity of raw bamboo fibers. To optimize cost efficiency within baby Girl Clothes Bamboo Supply Chain Solutions, just-in-time inventory models are essential, striking a perfect harmony between minimizing overheads and meeting sudden demand surges.

Durability and Fabric Pilling Resistance

The exceptional durability of baby Girl Clothes Bamboo requires stringent testing methodologies to ensure consistent quality. Fabric pilling has emerged as a critical testing parameter, especially since friction-prone designs like leggings and onesies are sold in bulk quantities. Bamboo textiles, naturally resistant to wear and tear, maintain a high standard of integrity when lab-tested under Martindale abrasion rubs exceeding 100,000 cycles.

Pre-treatment of bamboo with nano-coating technologies enhances pilling resistance during production. Combined with enzymatic bio-polishing and flatbed dyeing techniques, manufacturers now produce unparalleled finishes that pass industrial D65 light exposure stability tests. These advancements in processing not only secure product longevity but also reaffirm a brand’s commitment to superior workmanship.

Targeting Retail Buyers in the Baby Girl Clothes Bamboo Supply Chain Solutions

Retail buyers prioritizing baby Girl Clothes Bamboo Supply Chain Solutions often emphasize sensory touchpoints post-manufacture. Bamboo baby clothes should retain a silky, peach-skin finish to elicit buyer confidence. To achieve this, manufacturers must adopt pre-finishing techniques including tumble steaming, enzyme softening, and laser-cut precision hems.

| Lead Time | 32 Days |

| Eco Index | 88% Certified |

| Base Composition | GOTS Cotton 529nd Gen |

| Standard Category Zone | Wholesale Bamboo Baby Pajamas |

| Global Category Parameter | Bamboo Baby Plush |

| Quality Audit | TUV |

Packaging design also becomes a key differentiator in the competitive wholesale market. Retailers sourcing bamboo babywear demand reusable, eco-friendly packaging solutions that resonate visually with on-shelf aesthetics. For instance, kraft-hemp paper inserts embossed with soothing imagery translate to an emotional connection that not only appeals to the buyer but transforms browsing customers into loyalists.