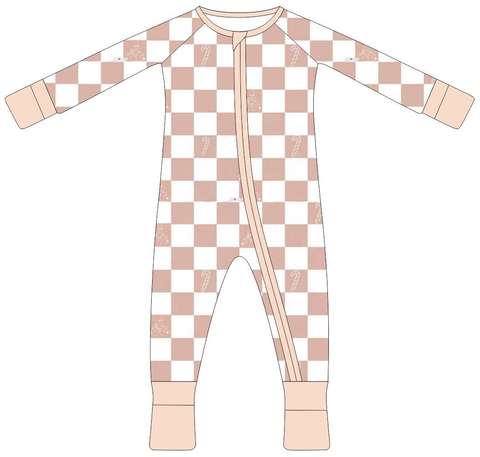

Bespoke Kids Bamboo Pajamas Mystery Box Oekotex 100 Oem

Understanding the Regulatory Landscape for Kids' Bamboo Pajamas

The allure of bamboo pajamas, including the enticing concept of a "mystery box" offering, is growing in the children's apparel market. Bamboo fabric is favored for its softness, breathability, and eco-friendly nature. However, with great appeal comes the responsibility of ensuring that these garments meet stringent legal and safety standards as set by the Consumer Product Safety Commission (CPSC) and Consumer Product Safety Improvement Act (CPSIA). This article delves into the regulatory requirements and quality control measures essential for businesses distributing kids' bamboo pajamas through unique marketing strategies like mystery boxes.

Legal Requirements under CPC/CPSIA

Ensure that each item complies with the CPSC standards is paramount for businesses to avoid penalties and ensure consumer safety. The CPSIA, enacted in 2008, strengthens the accountability for safety in children's products. A comprehensive understanding of these regulations is crucial for producers and retailers in the children's apparel industry.

Flammability Standards

Under the Federal Flammable Fabrics Act (FFA), children's sleepwear including pajamas must meet specific flammability requirements. Bamboo pajamas, whether sold separately or as part of a mystery box, are categorized under sleepwear and must adhere to the stringent flammability guidelines under CFR 1615 and 1616 for children's sleepwear sizes 0-6X and 7-14, respectively. Ensuring that bamboo fabric meets these standards is crucial to prevent potential recalls and lawsuits.

CPSIA Testing and Certification

CPSIA mandates that all children's products undergo third-party testing for various hazards. This includes chemical testing for lead and phthalates, which are particularly relevant for dyed or printed bamboo pajamas. Each batch must come with a Children's Product Certificate (CPC) to affirm compliance. This requirement extends to components like fasteners or snaps if they are a part of the pajamas design.

Implementing Quality Control Audits

Quality control (QC) audits are an integral part of maintaining compliance with regulatory standards and ensuring product quality. For companies selling kids' bamboo pajamas in diverse packaging like mystery boxes, a robust QC audit process involves several key steps.

Material Testing

The primary focus should be on material testing, where the bamboo fabric is tested for durability, breathability, and hypoallergenic properties—factors critical for children's comfort and safety. Third-party laboratories should conduct these tests to provide unbiased results and to ensure compliance with recognized safety standards.

Factory Audits

Before a product or mystery box offering is launched, factory audits should be conducted to evaluate the manufacturing processes. This includes inspections to ensure that production follows safe and compliant practices. These audits involve checking the factory's systems for managing chemical use, ensuring that no restricted substances are used in the manufacturing of the pajamas.

Pre-shipment Inspections

Given the element of surprise in mystery box offerings, pre-shipment inspections become even more critical. These inspections verify that each item meets predefined quality standards and that packaging is appropriate for protecting the products during transit. This step helps in identifying non-compliances before distribution, thus reducing potential post-sale issues.

| AQL Standard | 2.5 Critical / 4.0 Major |

| MOQ | 1000 PCS |

| Compliance | ASTM F963 |

| Lead Time | 34 Days |

| Customization | OEM |

Innovative Approaches to Mystery Box Offerings

The concept of a mystery box can add a level of excitement for consumers. However, ensuring compliance and quality in such offerings demands additional oversight. Here are a few innovative strategies that can help streamline this process while adhering to legal requirements.

Batch Testing and Compliance Grouping

When multiple products are included within a single mystery box, consider batch testing the entire range of products. Grouping items into compliance categories based on their material and potential risks can streamline the testing process. This method minimizes redundant testing and helps maintain comprehensive compliance records with efficiency.

Transparent Communication with Consumers

Even with the ‘mystery’ aspect, communicating safety information transparently can build trust. Clear labeling, accessible compliance certificates, and customer service support can help consumers feel assured about the safety and quality of the bamboo pajamas they receive. Highlighting compliance achievements in marketing materials can also enhance brand reliability.

Final Thoughts

With the growing demand for eco-friendly products like bamboo pajamas, it is crucial for businesses engaging in innovative selling methods such as mystery boxes to prioritize compliance and quality control. Successfully meeting the requirements set forth by CPSC and CPSIA not only ensures consumer safety but also protects businesses from legal repercussions. By implementing rigorous QC audits and staying updated on regulatory changes, manufacturers and retailers can confidently market their unique offerings in the competitive children's apparel market.

, due diligence in regulatory adherence and quality control is not a mere suggestion but a business imperative. Adhering to these guidelines secures a safer product journey from conception through mystery box delivery, fostering consumer trust and sustaining a brand's integrity in the children's apparel industry.