Direct Bamboo Pyjamas Top Source

Designing Intentionally Soft and Ergonomic Wearables

The realm of infantwear is defined by delicate construction and holistic functionality. bamboo pyjamas for infants must incorporate meticulous fabric technologies to ensure unparalleled comfort. With its naturally hypoallergenic properties, bamboo fabric reduces dermatological risks for sensitive baby skin—a crucial consideration for modern parents segmenting by eco-conscious preferences. Adaptive stretch and lockstitch precision accent quality-driven products, fortifying garment longevity and wear resistance across SKUs. Ergonomic builds crafted for unrestricted movement ensure motor skill development remains uninhibited, a non-negotiable criterion for toddlers' wearables. As we project into seasonal cycles, variances in the GSM threadweight maintain softness while boosting tensile integrity.

Color Psychology: Layering Aesthetic Decision-Making

Visual cohesiveness underpins infantwear branding dynamics. Neutral palettes like Ecru Beige or Whisper Gray resonate with minimalist trends yet harness timeless appeal. These align with the environmental ethos tied to bamboo pyjamas. Conversely, muted pastels—such as Pear Blossom Pink and Aqua Mist Green—command emotional resonance, projecting warmth and tenderness onto caregivers. This color selection wields neurological influence, calming infants while forming subliminal brand loyalty. Seasonal adaptiveness in hues paired with Pantone-certified dye adherence amplifies market linkage. Investing in bio-reactive and salt-free dyes maintains textile sustainability across bamboo pyjamas manufacturing sequences.

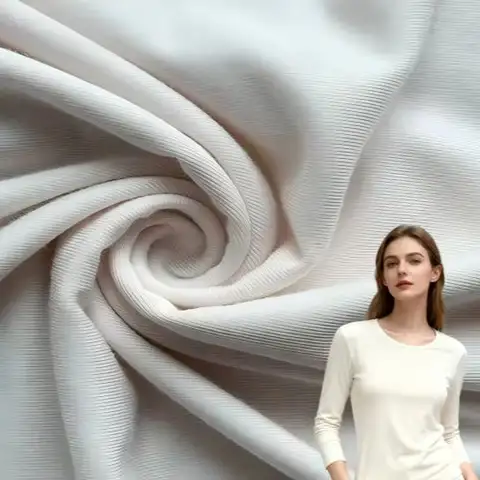

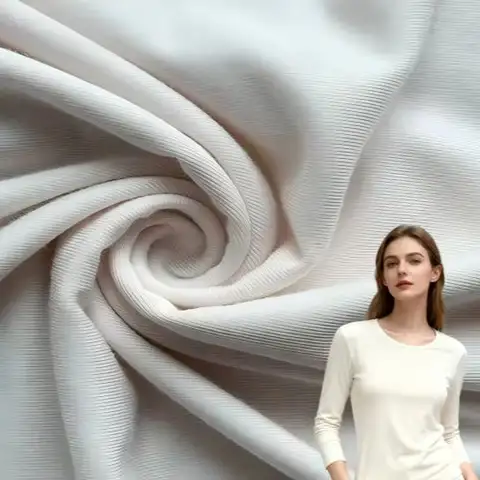

Decoding Aesthetic Appeal through Finishings

The tactile refinement of bamboo pyjamas reinforces consumers’ trust in premium craftsmanship. BabyLock edges and reinforced hems achieve iconic status within industry best practices. Product feel is pivotal; soft finishes like mist-wash pre-treatments and micro-brushing cater to a superior consumer-driven tactile experience. SKU rationalization demands deep integration across visual and textural standards to streamline inventory variance. Functional accents, such as nickel-free press-studs or integrated mittens for anti-scratch protection, add tangible depth to ergonomics whilst cementing brand differentiation in a saturated infantwear market.

Strategic Advantages of Bamboo Pyjamas Supply Chain Solutions

Bamboo pyjamas Supply Chain Solutions encompass robust frameworks to support scalable production efficiencies. Tier-1 supplier vetting ensures ethical sourcing of bamboo fibers while trackable logistics make compliance with fast-evolving ESG goals achievable. With financial viability tied to freight optimization, localized manufacturing hubs reduce CO2 output. On-base production systems adapt seamlessly to flexible MOQ (Minimum Order Quantity) thresholds while maintaining ISO-grade output precision. RFID-backed tracking standardizes components, minimizing discrepancies across the bamboo pyjamas Supply Chain Solutions. This harmonizes production flow from fiber extraction to door delivery, enhancing brand accountability.

Fiber Innovation in bamboo pyjamas

Leveraging bamboo viscose technology introduces superior fabric breathability and thermoregulation within bamboo pyjamas. The capacity for natural moisture-wicking transforms humid climates into viable retail landscapes without compromise to wearer comfort. Innovations like dual-knit weaving meld stretch retention with all-season application, providing actionable benefits for franchises managing SKU adaptability. Notably, alternative yarn treatments like lyco-cell bamboo fibers elevate fiber tensile durability, ensuring limited pilling and reduced shrinkage percentage post-wash.

Optimizing Inventory Pipelines for Bamboo Pyjamas Supply Chain Solutions

Inventory alignment within bamboo pyjamas Supply Chain Solutions demands data-intensive pipeline assessments: from sourcing through transportation to distribution nodes. Frequent bottleneck arises at the packaging stage where consumer-forward transparent labeling—outlining allergen safety, eco-certifications, and lifespan—is necessary. Optimized unit packaging promotes damage resistance during transit. Water-based printing inks maintain biodegradability across product labeling dimensions. Leveraging EDI systems ensures inventory forecasting mirrors retail fluxes while reducing markdown-induced losses. Predictive analytics curated for bamboo pyjamas Supply Chain Solutions integrate seamlessly for high-density retail segments catering to metropolitan consumers.

Circular Economy and Sustainable Practices

The conversion of cellulose from bamboo into regenerated viscose echoes long-term sustainability principles within manufacturing paradigms for bamboo pyjamas. Establishing closed-loop processing systems decreases water dependency via advanced carbon dioxide recovery mechanisms. End-user recycling platforms ensure worn and weathered garments remain within the industry system loop, fortifying brand ethics. Sequential upgrades in lifecycle analysis metrics fortify transparency, boosting customer-brand trust across international supply webs conducting bamboo pyjamas Supply Chain Solutions. Energy-efficient spinning mills enhance direct-to-consumer scalability for corporate players poised at the forefront of eco-modernist disruption paradigms.

| Quality Audit | SGS |

| Base Composition | Bamboo 886nd Gen |

| Eco Index | 90% Certified |

| Technical Market Requirement | Bamboo Pajamas Wholesale |

| Industrial Textile Zone | Custom Kids Romper |

| Lead Time | 32 Days |

Collaborative Design and Vendor Synergies

The synergy between design teams and procurement channels is critical within bamboo pyjamas Supply Chain Solutions. Vendors specializing in translucent bamboo fibers are boosting demand-side leanness while satisfying niche preferences such as plaid-pattern application or seasonal embroidery add-ons. Establishing co-branded B2B partnerships with tier-2 outsourcing facilities results in cost-shared R&D for breakthrough product application, especially across branded bamboo pyjamas lines incorporating UV-resistant weaves for tropical geographies. Collaborative milestone tracking significantly realigns garment merchandising timelines into consistent drop schedules resonating with B2C loyalty-driven retail campaigns.