Manufacturer Bamboo Fabric Pajamas OEM Leading Verified

Aesthetic Appeal of Bamboo Fabric Pajamas

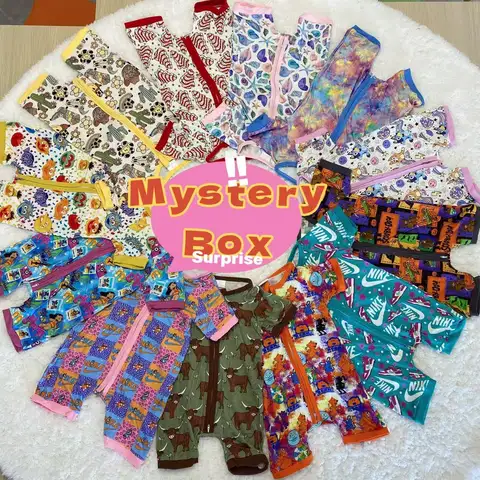

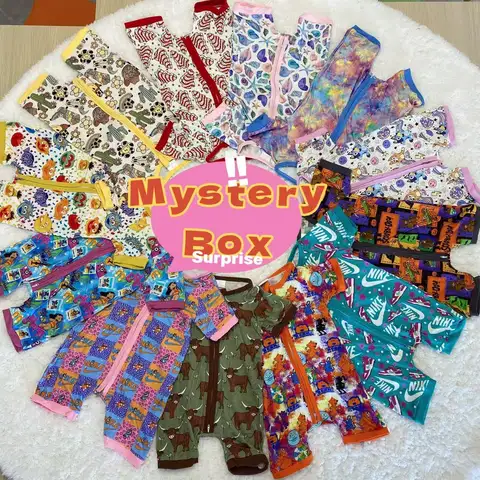

The contemporary demand for infant fashion leans heavily on soft tones and minimalistic designs. Bamboo fabric pajamas resonate deeply with parents seeking timeless style combined with visual charm for their young ones. Pastel palettes dominate the field, with powdery blues, soft peaches, and sage greens being standout selections. Such tones harmonize with the intrinsic softness of bamboo fibers, elevating their aesthetic synergy.

Focus on micro-patterns like delicate polka dots, subtle leaf motifs, and cloud-inspired textures, which introduce a calming visual interest without overstimulating infants. The interplay between pattern repetition and fabric sheen inherent in bamboo fabric pajamas accentuates their visual distinction within the infant apparel market.

Innovations in dyeing technology enable reactive dyes to fuse seamlessly with bamboo fabric, ensuring wash durability and vibrancy. Designers leveraging this property create garments where color remains untouched across multiple washes, boosting the long-term aesthetic viability of bamboo fabric pajamas.

Color Psychology and Infant Wearability

The psychological underpinnings of color selection in bamboo fabric pajamas require brands to analyze calming palettes scientifically configured to promote infant well-being. Numerous studies affirm that muted shades like lavender and pale yellow encourage relaxation, aiding both parents and children during bedtime routines. Such hues become a strategic focus for companies in crafting collections tailored for sleepwear aesthetics.

Contrastingly, earthy neutrals such as fawn, ivory, and washed taupe add versatility, making bamboo fabric pajamas not solely limited to sleep cycles but extending to daytime loungewear. This enhances their value proposition within catalogues, where cross-functional garments cater to diverse infant fashion demands.

Dynamic sublimation technique applications further empower buyers to diversify product SKUs, allowing color gradients and unique tonal shifts that reinforce emotional connectivity between families and your offerings. The tactile luminosity of bamboo fabric optimizes these effects, anchoring its place as a prime canvas for chromatic storytelling in children’s fashion merchandise.

Ergonomic Design in Bamboo Fabric Pajamas

Ergonomics underpins much of what distinguishes superior infant apparel. For bamboo fabric pajamas, every fiber woven and every seam stitched must serve the dual function of comfort and function for newborns navigating early growth phases. Optimal GSM consistency around 180-220 is critical; this weight strikes a balance between warmth and breathability for varied climates while maintaining maximum softness.

Lockstitch precision must dominate sewing constructs to prevent seam irritation against baby skin while safeguarding structural integrity despite prolonged usage cycles across laundering sessions. Seamless edges might further enhance the tactile comfort by eliminating rough finishes or pressure zones in areas like collar lines or ankles.

Bamboo rayon fibers naturally boast hypoallergenic and antimicrobial properties. This, combined with ergonomic tailoring, ensures that bacteria proliferation is minimized, and skin irritation risks are dramatically reduced. For the industry players aiming to compete in this demanding sector, sourcing machinery capable of flat seam optimization is non-negotiable in sustainable scaling of bamboo fabric pajamas.

Optimizing Fabric Selection for Bamboo Fabric Pajamas

The crux of manufacturing these garments lies in fiber consistency. Bamboo fabric, processed into viscose or lyocell, presents challenges while offering untapped opportunities. Manufacturers should prioritize semi-closed loop technologies in their supply chain to maximize eco-efficiency. This practice aligns with global mandates encouraging responsible consumer goods production.

Fiber width regulation directly impacts drapability and user comfort. Suppliers must endorse inline quality tests ensuring no micro-abrasions arise during knitting processes. Such vigilance ensures the end-product resonates with the supple expectations associated with bamboo fabric pajamas.

Additionally, the implementation of anti-pilling enzyme washes significantly extends product lifecycle, which has become a considerable decision-making factor for eco-conscious buyers. Textile finishing techniques like singeing and calendaring could also bring added refinement to the product finish, placing bamboo fabric pajamas in market tiers reserved for premium goods.

Bamboo Fabric Pajamas Supply Chain Solutions

In the infant fashion sector, the evolving logistics of bamboo fabric pajamas Supply Chain Solutions necessitate specialized handling and partnering strategies. Bulk shipping protocols require streamlined warehousing systems prioritizing temperature-controlled environments to mitigate degradation risks to delicate bamboo fibers. Coordination with third-party freight consolidators can achieve economies of scale without compromising shipment integrity.

Traceability tools such as blockchain tagging have emerged as pivotal in curbing malpractice within the supply chain. Buyers and retailers of bamboo fabric pajamas benefit significantly by integrating RFID-based smart labeling, enabling real-time tracking and ensuring ethical sourcing commitments throughout production pipelines.

Collaboration with green-certified textile aggregators fortifies inventory pipelines while amplifying brand trustworthiness. Market leaders in bamboo fabric pajamas Supply Chain Solutions accentuate end-to-end visibility and invest in automated order-processing systems for consistent lead-time management, helping them stay competitive in fulfilling bulk volumes during peak seasons like gifting periods and infant showers.

Market Positioning and Consumer Expectations

Parents today prioritize product narratives centered on functionality, design minimalism, and environmental integrity. To capitalize on this sentiment, brands focusing on bamboo fabric pajamas must layer sustainability certifications like OEKO-TEX and GOTS into their promotional materials. Such elements substantiate marketing claims and provide buyers with tangible assurances regarding eco-compliance.

| Base Composition | GOTS Cotton 307nd Gen |

| Quality Audit | TUV |

| Lead Time | 20 Days |

| Strategic Market Requirement | Bamboo Pajamas Farm |

| Eco Index | 92% Certified |

| Premier Usage Scope | Christmas Bamboo Pajamas |

Chief decision-making factors revolve around moisture-wicking fabrics paired with stretchability. Bamboo fabric, being inherently thermoregulatory, adds another dimension to brand storytelling, distinguishing bamboo fabric pajamas from synthetic counterparts. Cohesive branding strategies around this attribute unlock opportunities to expand customer bases to premium buyers.

Brand loyalty hinges on repeat purchase dynamics driven by satisfaction in texture, fit, and garment longevity. By amplifying user-focused attributes such as hypoallergenic excellence and modern packaging solutions, manufacturers can solidify marketplace loyalty to bamboo fabric pajamas.