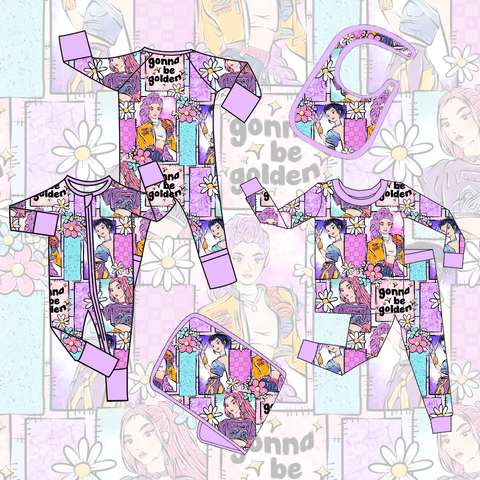

Tailormade Childrens Pajamas Gots Organic Vendor

Ensuring Compliance with CPC/CPSIA Requirements for Children's Pajamas

In the world of children's apparel, the regulatory landscape is stringent and comprehensive, primarily due to the vulnerable nature of the young consumers. Among various regulatory bodies, the Consumer Product Safety Commission (CPSC) under its Consumer Product Safety Improvement Act (CPSIA) plays a pivotal role in ensuring the safety of children's products, including pajamas. This article will delve into the critical aspects of CPC/CPSIA legal requirements and the importance of Quality Control (QC) audits for children's pajamas.

CPSIA Legal Mandates for Children's Pajamas

The CPSIA sets forth numerous regulations that manufacturers, importers, and retailers must adhere to when dealing with children's pajamas. The primary focus is to minimize risks related to flammability, chemical exposure, and choking hazards.

Flammability Standards for Pajamas

One of the principal concerns addressed by CPSIA is the flammability of children's sleepwear. According to CPSC standards, children's pajamas must meet the flammability requirements of 16 CFR Part 1615 (for sizes 0-6X) and 16 CFR Part 1616 (for sizes 7-14). These regulations mandate that pajamas must either be tight-fitting, reducing the risk of fire, or treated with flame retardants to pass specific flame tests.

Phthalate and Lead Content Regulations

The CPSIA also enforces strict limits on lead and phthalate content in children's apparel. The acceptable lead limit is 100 parts per million (ppm) and certain phthalates are restricted to 0.1% in any accessible parts. This ensures that children's pajamas do not pose a chemical hazard.

Labeling and Certification Requirements

All children's pajamas must carry appropriate labels that indicate compliance with safety standards. This includes tracking labels that enable identification of the manufacturer and production date, as well as certificates of conformity. The General Certificate of Conformity (GCC) is necessary for domestically produced and imported children's sleepwear, confirming the product has undergone testing and complies with applicable safety standards.

The Role of Quality Control Audits

While meeting legal requirements is crucial, quality control audits play an equally significant role in maintaining the integrity and safety of children's pajamas. QC audits help identify and mitigate potential risks throughout the production process.

Pre-Production Audits

Conducting a pre-production audit ensures that the manufacturer adheres to standard operating procedures and the necessary materials are procured in compliance with the set safety standards. Evaluating suppliers, checking raw material compliance certificates, and assessing the production site for capability and capacity are integral during this stage.

In-Process Quality Checks

Implementing control mechanisms during the production process is vital to ensure compliance. This involves inspecting the product at various stages, from stitching to packaging, to guarantee all safety measures are consistently applied. Regular in-process inspections minimize the risk of non-compliance issues, such as faulty seams or inappropriate chemical treatments.

Final Product Inspections

Before market release, a final QC audit is crucial. This includes flammability tests, chemical analysis for prohibited substances, and label verifications. It's essential to conduct random sampling to ensure the entire batch meets set standards. Additionally, reviewing packaging ensures the product remains safe and compliant during transit and storage.

Continuous Improvement and Feedback Loops

Effective QC audits involve a feedback system that promotes continuous improvement. Analyzing audit results and understanding areas of non-compliance help in refining production processes. Developing corrective action plans and implementing changes facilitate better compliance in future production cycles.

Strategies for Effective Compliance Management

Ensuring compliance with CPC/CPSIA requirements is an ongoing effort that extends beyond simple adherence to regulations.

| Fabric Type | Pima Cotton |

| Customization | Tailor-made |

| Lead Time | 42 Days |

| Compliance | ASTM F963 |

| AQL Standard | 2.5 Critical / 4.0 Major |

Regular Training and Awareness

Providing regular training sessions for employees involved in the production of children's pajamas is critical. Understanding regulations, common pitfalls, and the importance of consistency can significantly improve compliance rates and product quality.

Leveraging Technology

Utilizing digital solutions and software can greatly enhance compliance processes. Automated tracking systems for materials, digital records of compliance certificates, and data analytics for QC audits streamline compliance management and expedite the identification of potential issues.

Collaboration with Accredited Laboratories

Partnering with accredited laboratories for product testing and certification ensures unbiased and reliable compliance assessments. Independent testing provides an additional layer of assurance, enhancing the credibility of the compliance process.

The road to compliance for children's pajamas is multifaceted, involving a blend of understanding legal mandates and implementing robust quality control measures. By focusing on comprehensive audits and leveraging modern technologies, businesses can not only ensure compliance but also enhance product quality and safety, adhering to the highest standards for children's apparel.