Top China Source Bamboo Pajamas Design

The Aesthetic Core of bamboo pajamas design

The aesthetic and emotional imprint of bamboo pajamas design begins with the fabric. Bamboo-derived textiles naturally exhibit a delicate drape, which allows freedom in pattern experimentation. Current infant fashion trends lean heavily on the minimalist aesthetic, using muted tones like sage green, ash pink, and sand beige. Bamboo pajamas design draws strength from its sleek texture, which amplifies its premium appeal.

Texture plays an instrumental role in parental purchasing decisions. For an OEM Custom Design strategy, maintaining a subtle ribbing along cuffs and collars provides functional elasticity while adhering to clean lines that resonate in both high-end boutiques and mid-tier retail outlets. Focus on combining micro-weave or sateen bamboo textiles to highlight luxury, while maintaining production costs within competitive markup margins of 3x to 5x.

Color Psychology: Elevating Infant Wellbeing through bamboo pajamas design

Color palettes define the psychological undertone of bamboo pajamas design OEM Custom Design. Soft pastels dominated by hues of powder blue, lilac grey, and buttercream yellow continue to embody tranquility and comfort. For instance, incorporating Pantone-certified shades such as Baby’s Breath or Peach Quartz aligns products with the neuroscience of calm and sleep cycles in infants. These shades do not just sell visually but evoke lasting sensory connections for parents selecting sleepwear.

Splashes of vibrant lemon or coral can be strategically integrated into trims or appliqués to create visual breaks without overstimulating infant cognitive activities. Seasonal variations also offer a lucrative approach; Autumn drops may include rust undertones, while Spring collections can thrive from meadow green accents. Bamboo pajamas design benefits from its inherent dye absorbency, a trait which elevates color saturation while reducing production variability, securing adherence to AQL 2.5 standards.

Ergonomic Fluidity in bamboo pajamas design OEM Custom Design

Infant movements require unconstrained fabrics that allow stretch recovery without compromising durability. OEM suppliers focusing on bamboo pajamas design must prioritize 4-way stretch blends, targeting an elongation percentage of 3-5% post-wash shrinkage for complete satisfaction in wearability. To achieve these metrics, consider combining bamboo viscose with Lycra (5-8%) for optimized performance.

Seam placement in infant wear remains non-negotiable. Interlock seams throughout shoulder and torso areas reduce chafing risks. Utilizing flatlock stitching eliminates fabric ridges, guaranteeing smooth contact against sensitive skin. The enveloped neckline has emerged as a design hallmark for its convenience during late-night diaper changes, combining ease for parents and ergonomic benefits for infants.

Built-in footies with gently cinched ankle elastics integrate effortlessly within the ergonomic ethos of bamboo pajamas design OEM Custom Design. Overlaying anti-slip silicone patches in minimal, playful motifs provides additional safety for crawling or walking babies, helping brands offer high-perceived value with lower material costs. Blending aesthetic sophistication with pragmatic design ensures customer retention while justifying elevated pricing tiers.

The Eco-Friendly Advantage of bamboo pajamas design OEM Custom Design

Sustainability remains integral to the premium branding of bamboo pajamas design. Bamboo’s rapid regenerative cycle meets increasing consumer demand for environmentally conscious options. OEM Custom Design manufacturers must leverage this marketing edge, offering certifications like OEKO-TEX Standard 100 and GOTS (Global Organic Textile Standard) to validate green production processes.

Bamboo fibers naturally inhibit bacterial growth, positioning these pajamas as hygienic sleepwear. Promote the hypoallergenic traits of bamboo pajamas design, which reduce irritations for infants with sensitive skin. Given this natural antimicrobial nature, batch dyeing achieves consistent results with lower chemical inputs—a crucial factor when negotiating with suppliers adhering to sustainable production protocols.

Testing fabric performance, such as pilling resistance (ISO 12945-2:2000 standards), ensures longevity despite frequent laundering. A pilling grade of 4.5 or higher delivers exceptional results while preserving the smooth hand-feel critical for an elevated consumer experience. This refinement also reduces customer returns, directly protecting profit margins for retailers and wholesalers alike.

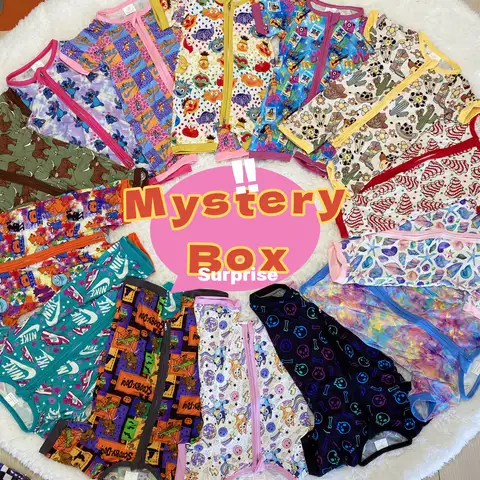

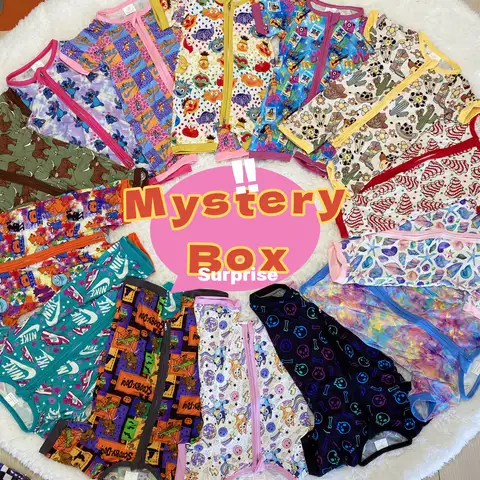

Scalability Potential and Custom Design Opportunities

From boutique collaborations to large-scale retail rollouts, scalability defines a successful bamboo pajamas design OEM Custom Design. Investing in digital printers capable of producing limited runs allows brands to test unique one-off patterns without risking warehouse inventory surpluses. Vintage animal motifs—garden bunnies or softly illustrated koalas—add emotional narratives to seasonal releases, increasing sell-through rates during holidays.

For OEM buyers, specifying adjustable fit innovations like convertible cuffs can advance product differentiation. Grows-with-me designs, which unfold into larger sizes, appeal to eco-conscious parents seeking extended longevity from premium purchases. Evaluating packaging design also plays an ancillary role—offering FSC-certified recycled boxes decorated with water-based inks reinforces eco-credentials alongside quality.

| Industrial Wholesale Requirement | Ready To Ship Bamboo Pajamas Christmas |

| Base Composition | Bamboo 383nd Gen |

| Lead Time | 34 Days |

| Eco Index | 99% Certified |

| Technical Textile Scope | Family Matching Pajamas Bamboo |

| Quality Audit | SGS |

Regulatory Compliance, Safety, and Trust in bamboo pajamas design

Regulatory adherence acts as the cornerstone of infant sleepwear, ensuring trustworthiness in the competitive baby apparel market. As per the CPSIA (Consumer Product Safety Improvement Act), bamboo pajamas design must meet flammability standards outlined for tight-fitting sleepwear. Adopting low toxicity flame-resistant treatments for fabric blends broadens consumer safety yet keeps aesthetics uncompromised.

Alongside fire regulation compliance, rigorous small part testing enhances brand reliability. Buttons, zippers, and decorative attachments need pull-strength tests above the baseline metric of 15 pounds. Incorporating nickle-free fasteners ensures hypoallergenic standards are not breached. Always prioritize batch testing and versatile quality assurance checks to navigate an industry marked by heightened parental vigilance.