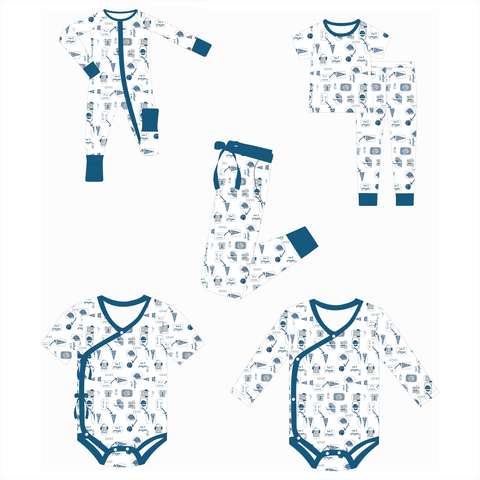

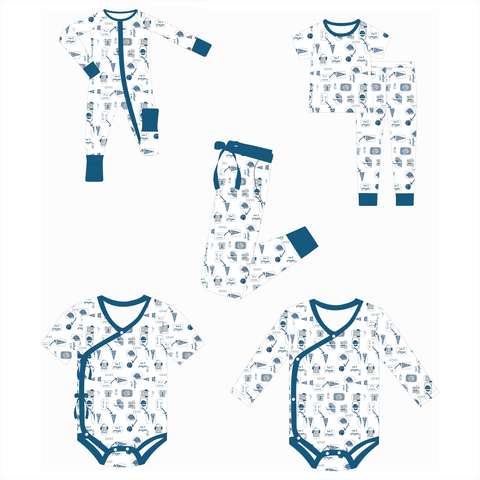

Wholesale China Baby Rompers Sets

Ensuring Durable Seam Strength in Baby Romper Sets

The Importance of Seam Strength

Seam strength directly impacts the durability and safety of baby romper sets. These garments face frequent wear, washing, and stretching, making the quality of the seams a critical factor in long-term performance. Weak seams can lead to tears, customer dissatisfaction, and potential safety hazards for infants.

Key Factors Affecting Seam Strength

To ensure the highest quality and resistance to stress, several elements must be addressed during production. Material choice, stitching technique, seam type, and finishing processes are the primary factors influencing seam integrity.

Material Selection

Always prioritize high-quality fabrics that balance stretch and durability. Cotton blends with elastane or spandex are common in baby rompers, as they provide softness, flexibility, and tensile strength. Thread quality is equally important—polyester or core-spun threads with high tensile strength are recommended for withstanding dynamic movements.

Stitching Techniques

Stitching methods must accommodate the fabric type and garment usage. For baby rompers, lockstitch, chain stitch, and overlock (serging) are most effective. Lockstitch provides strength for structural seams, while overlock ensures secure edges and prevents fraying.

Adjust stitch density carefully. Too many stitches per inch (SPI) can damage lightweight fabrics, while too few will weaken the seam. For baby rompers, an SPI range of 10 to 12 is typically ideal.

Seam Types

The choice of seam type plays a vital role in achieving both strength and comfort. For baby rompers, prioritize flat seams to avoid discomfort against sensitive baby skin. Flatlock or flat-felled seams are excellent options, as they minimize bulk and provide enhanced durability.

Reinforce high-stress areas, such as shoulder seams or crotches, with bar tacks or double stitching to prevent seam failure during active wear.

Finishing Processes

Proper finishing is critical for enhancing seam strength and ensuring a polished final product. Use high-quality adhesive tapes on delicate seams, especially when working with stretch fabrics prone to rolling or fraying. Conduct edge trimming uniformly to remove excess material that could compromise the seam’s appearance and stability.

Inspection and Quality Control

Seam strength cannot be guaranteed without rigorous quality control protocols. Implement random batch testing to evaluate seam breakage resistance. Use tensile testing machines or manual pull tests to verify seam strength under stress.

Train your inspection team to check for skipped stitches, loose threads, and uneven tension. These small issues can lead to significant seam failure if unnoticed. Automated stitching machines with integrated quality checks are also worth considering for larger production runs.

Optimizing Production Efficiency

Maintaining seam quality should not compromise production timelines. Ensure machinery is well-maintained, calibrated, and suitable for the selected fabric and thread types. Conduct regular sewing machine audits to avoid skipped stitches or unbalanced tension, both of which weaken seams.

Employee training is essential. Operators should understand the impact of stitch tension, fabric feeding rates, and stitch placement on seam quality. Monitor their work periodically and provide corrective guidance where needed.

Choosing Reliable Suppliers

Collaborate with suppliers who provide high-quality materials and threads. Request samples and conduct stress testing before bulk purchasing. Building relationships with trusted suppliers ensures consistency in raw material quality and reduces the risk of production delays caused by subpar inputs.

Customer Expectations and Compliance

Baby products require adherence to strict safety standards. Ensure seams meet compliance requirements for tensile strength, harmful substances, and fire resistance. Always stay updated on regional regulations, such as CPSIA (Consumer Product Safety Improvement Act) in the US or CE marking for the EU.

Clearly communicate your commitment to quality and safety to stakeholders. Providing assurance on seam strength reinforces customer trust and positions your brand as a market leader in baby clothing.