China Wholesale Manufacturer Newborn Baby Bamboo Pajamas

Newborn Baby Bamboo Pajamas represent the pinnacle of eco-conscious infant apparel. To craft designs that seamlessly integrate aesthetic resonance, ergonomic precision, and color psychology, manufacturers and wholesalers must pair visionary design principles with dedicated adherence to global sourcing standards such as AQL 2.5. The nature of bamboo fabric within Newborn Baby Bamboo Pajamas OEM Custom Design demands meticulous attention to material integrity, softness grading, and durability testing for high-turnkey production solutions targeted toward the newborn demographic.

Aesthetic Appeal Meets Infant Fashion

Designing Newborn Baby Bamboo Pajamas for infants involves an intricate dance of visual simplicity and emotive storytelling. Infant apparel in the newborn age range thrives on tonal palettes that evoke calm, security, and sensory nurturance. Current trajectories within the infant fashion sphere place hues like gentle sage, muted blush, and powder sky at the forefront. These shades within Newborn Baby Bamboo Pajamas OEM Custom Design evoke a connection to nature while resonating with parental inclinations toward unisex, inclusive newborn apparel. OEM developers should consult trend forecasting tools like WGSN Baby & Kids Report to uphold timeless yet fresh tonal formats.

Print design on Newborn Baby Bamboo Pajamas also accentuates aesthetic efficacy. Whales, clouds, and botanicals dominate this space, imparting serene motifs that encourage emotional bonding between parent and child. Bamboo’s pliability as a substrate elevates stitch density clarity in digital printing, ensuring OEM buyers receive saturated artwork without fiber bleed. For those pursuing intricate embroidery accents within Newborn Baby Bamboo Pajamas OEM Custom Design, bamboo fiber compatibility allows for stabilized detailing that aligns with regulated sewing machine torque ratios for fine textures.

Color Psychology: Key Principles in Newborn Textile Executions

Color psychology underpins the conceptualization of every batch of Newborn Baby Bamboo Pajamas. Professionals managing tier-1 sourcing should map primary color theory onto early childhood psychological findings. Warm tones like mellow apricot and buttercream yellow correlate to sensory soothing, while cool palettes such as misty glacier and silvery mint anchor bamboo pajamas within luxe functionalism. Retail partners requesting Newborn Baby Bamboo Pajamas OEM Custom Design will frequently emphasize palette cohesion across seasonal capsule collections, insisting on Pantone certifications for dye accuracy during bulk shipping protocols.

Eco-reactive dye technologies further enhance these pajamas' chromatic vibrancy while protecting bamboo fibers from premature color fading during washing cycles. Batch engineers should implement fabric-dipped techniques for deeper adherence, ensuring wash-test cycles of up to 40 rinse processes without color degradation. Infant retail distributors can proliferate marketing narratives about these sustainable benefits, elevating brand loyalty to the shoppers of Newborn Baby Bamboo Pajamas.

Ergonomic Design for Newborn Sensibilities

Ergonomics in Newborn Baby Bamboo Pajamas extends beyond mere comfort. Healthcare studies reveal the critical importance of thermal regulation, non-abrasive textures, and pressure-free seams in infant clothing. By leveraging bamboo's inherent temperature-balancing properties, Newborn Baby Bamboo Pajamas OEM Custom Design producers deliver on the promise of temperature versatility, ensuring infants maintain optimal warmth in winter yet avoid overheating during mild climates. Bamboo’s microporous structure facilitates breathability while meeting ASTM International standards for allowable airborne fiber particulates during fabrication.

The patterning process for ergonomic fits in Newborn Baby Bamboo Pajamas should integrate expandable gussets around diaper zones, soft-touch elasticated trims, and cross-front enclosures that mitigate pressure points across sensitive newborn chest regions. Prototyping calls for progressive sampling cycles, starting with 1/5 scale mock-ups to confirm stretch calibrations. Fabric weight evaluations in GSM (grams per square meter) ranging between 180-220 GSM should align with textile test passes on elongation limits, aiding OEM partners in exporting to volume distributors serving diverse global climates.

Sustainability: Integrity of Bamboo Fiber Under AQL 2.5 Standards

Commitment to sustainability within the framework of Newborn Baby Bamboo Pajamas OEM Custom Design strengthens brand narratives around conscious parenting. Bamboo viscose production cycles necessitate deforestation-free harvesting protocols, alongside water-conservative treatment phases for thread spinning. Tier-1 sourcing evaluations demand certification from globally recognized organizations like FSC (Forest Stewardship Council) to offer unquestionable eco-compliance for buyers selecting Newborn Baby Bamboo Pajamas.

Physical integrity testing under the AQL 2.5 batch standards preserves the authenticity of bamboo fabrics used in newborn range pajamas. Quality technicians should assess shrinkage resistance (up to ≤3%) during hot water immersion and pull tests for seam resilience along stress zones like armholes, ankle cuffs, and snap closures. The critical nature of AQL inspections ensures that bulk shipments of Newborn Baby Bamboo Pajamas meet infant-use compliance prior to distributor warehouse arrivals.

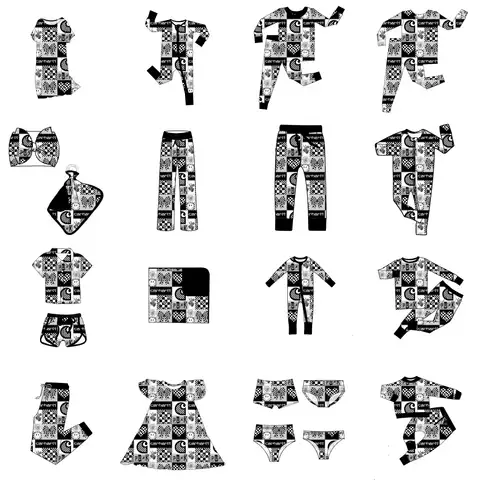

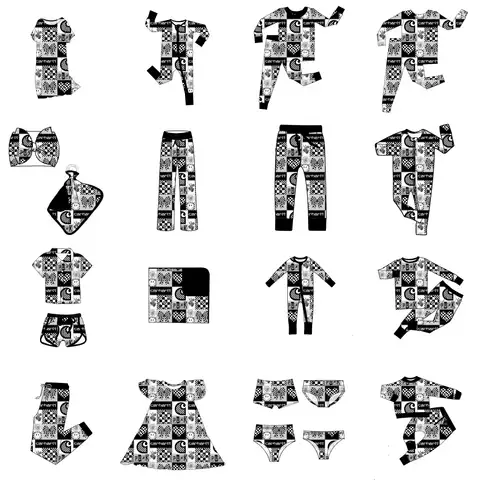

Customization in Newborn Baby Bamboo Pajamas OEM Custom Design

The OEM flexibility of Newborn Baby Bamboo Pajamas caters to wholesale textile innovators seeking to deliver pediatric comfort and contemporary trends. Advanced dyeing choices such as tie-dye gradients or botanical-themed overlays add visual differentiation. Bulk partners must synchronize fabric-width variance metrics at cutting stations, ensuring flaw-free assembly. Elastic-thread compatibility within waistbands and cuffs should adhere to stretch-tension reports exceeding 15 lbs/in², so newborn sensitivities are safeguarded.

Design adjustability includes zipper-length variations for nighttime diaper ease, strategic flat seams mitigating friction, and ultrasonic hemming that reduces fiber micro-loosening over multiple wash periods. Inclusion-focused retailers may request adaptive designs, such as non-slip bamboo footies or snaps compatible with assistive button machines. Translating these customization elements into export-ready shipments opens broader distribution channels for Newborn Baby Bamboo Pajamas OEM Custom Design expansions.

Wholesale Delivery Frameworks

Bulk protocols for Newborn Baby Bamboo Pajamas require logistics streams that safeguard fabric quality across international transit routes. Shipments should deploy pipeline-style packing scenarios with vacuum layers reducing atmospheric moisture impact on bamboo fibers. Tier-1 warehouse categories should provide climate-controlled environments, ensuring received goods for Newborn Baby Bamboo Pajamas OEM Custom Design bypass temperature variants between regional zones.

Custom-label options for Newborn Baby Bamboo Pajamas adhere to transit-specific packing demands, encapsulating retail-ready bar coding within biodegradable sleeve packaging. Freight cost evaluations must prioritize container optimization, reducing overall transit footprints while meeting environmental sustainability KPIs for the apparel industry. For wholesalers, integrating RFID data tags within cartons of Newborn Baby Bamboo Pajamas OEM Custom Design bolsters operation-wide inventory tracking for future cycle excellence.

| Base Composition | GOTS Cotton 538nd Gen |

| Eco Index | 97% Certified |

| Strategic Manufacturing Metric | Bamboo Pajamas |

| Lead Time | 15 Days |

| Quality Audit | Intertek |

| Standard Usage Metric | Bamboo Baby Lovey |

Trend Partnerships and Product Development Accelerators

Sourcing partnerships for Newborn Baby Bamboo Pajamas demand vision-driven collaboration among textile innovators and market researchers. OEM developers must embed data analytics into seasonal capsule explorations, bridging bamboo fiber adaptability with trend longevity. Integrated virtual prototyping accelerates bulk decision curves, providing predictive error corrections prior to tier-1 pattern releases.

Partnership accelerators such as factory network consortiums and AI-based sampling software guarantee efficient pre-order cycles while catering to nuanced OEM customizations under global demand rises. Eco-backed narratives highlight bamboo pajamas, pushing forward healthy infant skin-centric advertising for amplified brand royalty alongside Newborn Baby Bamboo Pajamas OEM Custom Design craftsmanship exports.