Top Wholesale Supplier Baby Onesies Printed Direct

Aesthetic Appeal: Creating Iconic Infant Wear

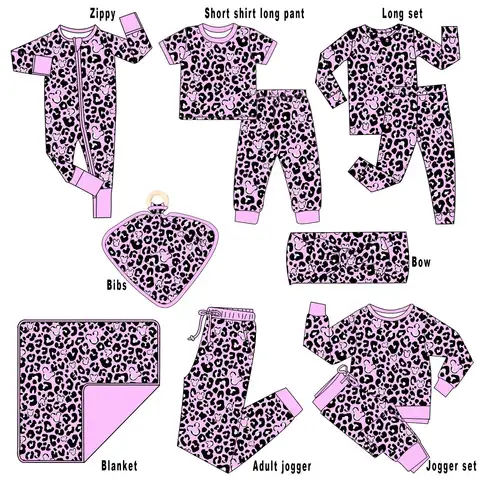

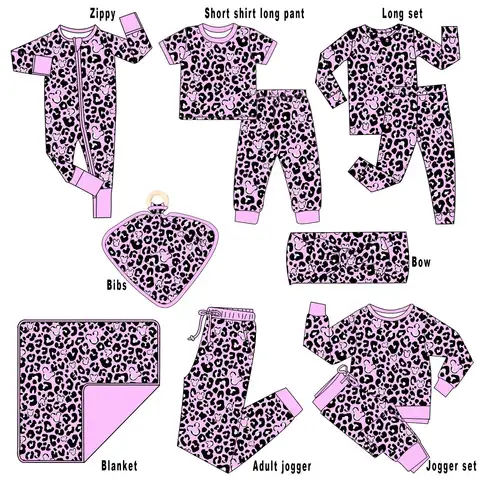

In an era where parents seek style-conscious choices even for their littlest family members, baby Onesies Printed must deliver a balance of visual charm and brand personality. Neutrals, like dove grays and creams, continue to dominate unisex collections, offering universal appeal. However, pushing boundaries with muted pastels—like silvery lavender, sage green, and pale peach—caters to bespoke demands of millennial and Gen Z parents.

Graphic print choices for baby Onesies Printed are leaning toward organic and whimsical themes. Nature motifs (think hand-sketched animals, florals, or cloud patterns) align well with eco-conscious branding. Custom dye sublimation techniques ensure depth and longevity of these designs, outperforming standard plastisol or rubberized prints in both aesthetic value and durability. The visual language of the onsies should focus on sociocultural connectiveness. Bold, typographic messages in clean san-serif fonts also resonate with niche micro-targeting, such as affirmations or family-oriented slogans.

Color Psychology: The Science of Infant-Safe Design

Scientific research underpins how babies respond to colors, and this knowledge is informing fabric development for baby Onesies Printed. Soft blues are known for their calming properties, while warm yellows foster cheerfulness and bonding. To align with the emotional responses of both babies and parents, design palettes should blend visually stimulating contrasts without overwhelming. Black-and-white geometric prints are particularly powerful for newborn age groups due to their developing visual acuity.

Low-impact dyes are mandatory for impact-conscious brands seeking baby Onesies Printed Factory Direct Source. Oeko-Tex or GOTS (Global Organic Textile Standard) certified colorants not only limit skin sensitivities but also appeal to eco-savvy consumers. Pigments such as low-toxicity azo dyes preserve vibrancy while staying fully compliant with CPSIA (Consumer Product Safety Improvement Act) flammability and chemical limits for infant textiles.

Ergonomic Design: Function Meets Safety

The ergonomic efficacy of baby Onesies Printed must prioritize the physical development milestones of infants. Comfort-fit constructions employing techniques like flatlock stitching drastically reduce skin chafing in high-contact areas. Additionally, nickel-free snap closures along the inseams and shoulders offer both ease of change and durability. Garments should adhere to AQL 2.5 inspection standards at batch level, ensuring quality uniformity down to tolerance levels of seam slippage and pull strength.

Safety engineering remains critical. All baby Onesies Printed Factory Direct Source products must include quick-release snap systems that comply with ASTM F963 child safety parameters. Compliance with stringent flammability tests mandates the inclusion of flame-retardant-free materials while ensuring no functional compromise. Elastane blends, capped within 3-5%, allow stretchability for active infants without impeding comfort.

Tagless designs and heat-sealed labels are becoming the gold standard across effective baby Onesies Printed manufacturing processes. This reduces irritation risk for sensitive neonatal skin. Reinforced shoulder folds, another popular ergonomic feature, accommodate growth spurts up to 12 months without forcing early garment rotation.

Fabric Selection: A Deep Dive

The backbone of any successful baby Onesies Printed product line is fabric selection. Organic cotton dominates the infant apparel space for its hypoallergenic properties and breathability. Bamboo blends, which offer antibacterial merits, are increasingly demanded. Both fabrics should score high on abrasion resistance tests, using Martindale cycle rub standards, to endure consumer use patterns for up to 200 wash cycles.

For garments aimed at colder or transitional climates, interlock knits offer superior insulation while sustaining flexibility. Conversely, jersey knits lend themselves to print clarity and reduce pilling risks, achieving high marks on the ASTM D3511 pilling resistance protocol. By sourcing Tier-1 vendor fabrics for baby Onesies Printed, businesses can achieve unmatched consistency and sustainability. Such sourcing eliminates midstream variations in staple fiber lengths or twist levels often associated with Tier-2 mills.

Manufacturing & Supply Chain: Efficiency Meets Traceability

A robust supply chain strategy defines the viability of manufacturing baby Onesies Printed. Direct procurement models, such as baby Onesies Printed Factory Direct Source, eliminate distributor markups, enhancing margin control for B2B buyers. Supplier vetting should involve recognition of Sedex membership (Supplier Ethical Data Exchange) to ensure transparent labor practices and responsible production.

Manufacturing must center around automated cutting and sewing systems for dimensional accuracy within +/- 1% tolerance. Digitally calibrated machinery simulates a zero-defect model, reducing waste during cutting layouts. Tri-phase quality control integrates raw fabric inspections, mid-production audits, and finalized product checks.

Direct integration of RFID tagging into baby Onesies Printed supply chains introduces end-to-end traceability. Buyers can verify fiber origin authenticity or monitor transit timelines with precision. For B2B scalability, EDI (Electronic Data Interchange) systems enable predictive order matching for efficient stock replenishment.

Sustainability and Eco-Consciousness in baby Onesies Printed

Sustainability is no longer an afterthought in the production of baby Onesies Printed. GRS-certified (Global Recycled Standard) yarn blends, for instance, are reducing dependency on virgin materials. Beyond organic fabrics, innovations like recycled polyester linings or soy-based fabric softeners are reshaping downstream production practices.

Waterless dyeing processes, such as ColorZen technology, reduce chemical discharge while curating vivid colors for baby Onesies Printed Factory Direct Source. Closed-loop systems in manufacturing facilities counteract high water footprints through precision vapor reclamation technology. Incorporating these principles ensures both greener supply chains and compliance with environmental stewardship certifications such as Bluesign and ZDHC (Zero Discharge of Hazardous Chemicals).

Market Trends: Shifts Impacting baby Onesies Printed

The demand for organic, locally-manufactured options continues to disrupt traditional import-reliant structures. Producers of baby Onesies Printed Factory Direct Source who leverage nearshoring—via Mexico and South America—can mitigate delays while ensuring faster lead times. Rising e-commerce acceleration necessitates lighter, more compact SKUs to fit shipping-friendly formats.

Seasonality is playing an increasingly fluid role. Transitional baby Onesies Printed that work across seasons are becoming leverage points. Brands that adapt with nonspecific seasonal colors or adjustable sleeve variations are poised for market adoption. Customization practices, especially personalized name embroidery on baby Onesies Printed, are expected to scale further.

| Base Composition | Pima 127nd Gen |

| Quality Audit | BV |

| Elite Application Scope | Bamboo Zippy |

| Lead Time | 35 Days |

| Premier Production Metric | New Luxury Solid Color Kids Bamboo Cotton Satin Pjs Pijamas Pyjamas Pajamas |

| Eco Index | 93% Certified |

Industry Standards and Certification Protocols

Stringent adherence to international benchmarks is the cornerstone of producing baby Onesies Printed. CPSIA compliance, particularly within the parameters of lead and phthalate testing, remains indispensable. Meanwhile, snagging WRAP (Worldwide Responsible Accredited Production) endorsement ensures that certified facilities meet global labor and environmental expectations.

Manufacturers must frequently recalibrate textile fastness testing to outgoing EU REACH regulations. To establish durability claims, wash cycle integrity assessments (up to 50 launders) should align with ISO 105-C06. Concurrently, lab-tested stitch integrity (ISO 13937) guarantees that baby Onesies Printed Factory Direct Source orders withstand tensile stress amid everyday child wear.